Sawmill manufacturers are facing several unique challenges as the lumber industry wrestles with shortages caused by supply chain issues. With lumber in high demand, sawmills are tasked with expediting operations to increase volume yield while maintaining operational efficiency.

While increasing production speed can help increasing yield, it also increases the risk of product inconsistency and costly equipment breakdown. Many sawmill operations also present harsh environments that feature tree sap, dust and other threats that can result in equipment contamination.

At a time when sawmills must operate at full capacity, even a brief interruption in production can carry significant consequences. Therefore achieving maximum equipment performance is critical to avoiding costly losses in production yield. To maintain maximum equipment performance, sawmill manufacturers must implement a system for productive maintenance and choose products that promote consistently strong equipment performance.

Tsubaki offers a wide range of forestry products that meet the most demanding application challenges in the industry such as shock load, fatigue limit, abrasion, extreme speed and more. Tsubaki products overcome these challenges and keep your sawmill equipment operating at its full potential, reducing the risk of unexpected downtime. Discover how these solutions can help your sawmill operation avoid breakdowns and defects in product quality.

Case Studies

Roller Chains: Built to handle a challenge

Tsubaki roller chains are most commonly used for the transmission of mechanical power of industrial machinery. These products are known for delivering consistently reliable equipment performance for sawmill operations. No matter how demanding the application, Tsubaki forestry roller chains are up to the task.

- Sharp Top Chain: Tsubaki Sharp Top chains with a wide range of tooth configurations are designed to operate longer and withstand harsh environments. They consist of straight sidebars for additional strength and heat-treated side plates for better protection against the fatigue wear that may induce cracks in high-speed applications. Furthermore, Tsubaki Sharp Top chains in sizes 80 and larger feature patented lube groove bushings, which act as a reservoir for excess lubricant, minimizing pin and bushing wear while reaching a longer chain lifespan. Tsubaki Sharp Top chains are the right solution for today’s sawmill operations.

- Titan® Harsh Environment Chain: Tsubaki Titan® chains deliver better performance with increased wear life in high-speed, abrasive applications. The special coated pins offer lower friction and higher hardness to improve chain wear characteristics. Special coatings on the side plates also provide better corrosion resistance in outdoor settings.

- Lambda® Self-Lubricating Chain: Tsubaki Lambda® chains with special oil-impregnated bushings are an ideal choice in forestry industry when machines and conveyed materials must be free from contact with oil, or when lubrication is difficult. Tsubaki Lambda® chains in a machine such as a planer also add a great value in reducing contamination of the product or equipment.

- Xceeder® Longer Life Chain: Designed to last up to 10 times longer than other lube-free chains, the Xceeder® chain extends the wear resistance of the Lambda® chain by adding oil-impregnated felt seals between the link plates. The special, patented high-density felt seals lock in lube while keeping dirt and abrasives out. This chain is suited for operating environments that require extended replacement intervals.

Tsubaki roller chains meet demanding forestry industry requirements such as shock load, fatigue limit, abrasion and extreme speed while reducing maintenance and unnecessary downtime in even the harshest environments.

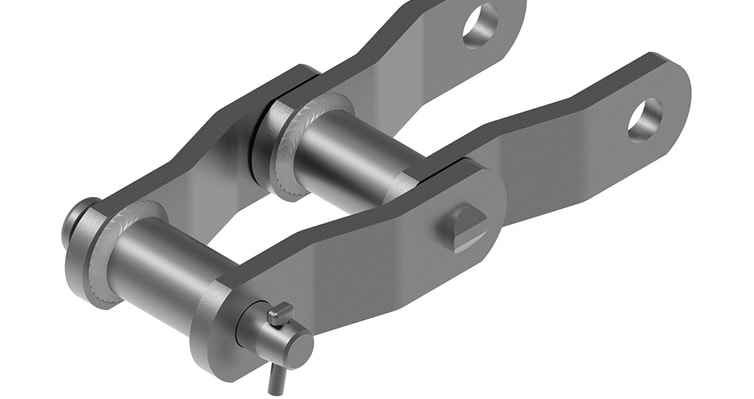

Engineering class chains: Providing performance you can count on

Tsubaki engineering class chains are utilized exclusively on conveyors throughout the milling and production process and can be trusted in the most demanding operating conditions. Welded steel mill chains are designed for heavy duty conveyor service in the forestry industry.

- Welded Steel Mill Chain: The backbone of forestry operations, the inherent design of Tsubaki welded steel chains provides high tensile and fatigue strength. Tsubaki Mill Chain Sidebars and Barrels are shot peened for additional fatigue strength. Pins are also precision fit for a superior press fit into the side bar. Special platings or coatings can also be applied to prevent corrosion.

Tsubaki welded steel chains ensure the most reliable equipment lifecycles in the industry by withstanding high shock loading, providing resistance to abrasive material, and operating in extreme temperatures and climates.

Sprockets: Strong enough to handle the heaviest loads

Tsubaki drum sprockets are used to convey heavy bulk scrap materials as well as wood, timber and logs. These drum sprockets are best suited for carrying logs to the debarker equipment and transferring waste such as edging, trimmings and bark out of the facility on drag conveyors. They come in a variety of styles and can be customized to best suit your unique applications.

- Jackladder drag conveyors: Convey logs from the “log pond,” to the debarker in-feed conveyor.

- Debarker in-feed conveyors: Feeds wood logs of various types and lengths through a ring debarker.

- Hog/Woodchip/Sawdust conveyors: Transport hog (bark & wood trimmings), woodchips or sawdust.

- Truck dump conveyors: Used in pulp and paper mills to convey hog and/or woodchips collected from truck dumps.

- Welded steel sprockets: Used for conveyors which transfer high volumes of rough-cut lumber throughout the sawmill.

Tsubaki drum and welded steel sprockets are designed with strength in mind, utilizing thick teeth, plates and hubs that are manufactured to support the high torque requirements of drag and welded steel chains. They are built to last with quality in mind and use only the highest-grade steel, which is critical in today’s demanding forestry mills.

Backstops & Clutches: Maintaining efficiency while preventing contamination

Tsubaki backstops are used in pulp and paper mills to move raw or in-process materials around a site. Tsubaki overrunning clutches are also used in sawmill machinery to control the transmission of torque in one drive direction while simultaneously allowing the output axis to continue turning in the original direction. These products help reduce contamination and maintain efficiency.

- BS-F Backstops: Used on incline conveyors at pulp and paper mills to prevent reverse rotation of the conveyor. The grease lubrication and labyrinth seal are specifically designed to prevent ingress of small materials into the clutch to provide a long lifespan.

- BB Series Clutches: BB Series clutches are a combination of a 62 Series ball bearing and a cam style clutch. Designed for press fit applications, these overrunning clutches provide overrunning capability to allow for speed differences between the operation of the equipment and the supply power.

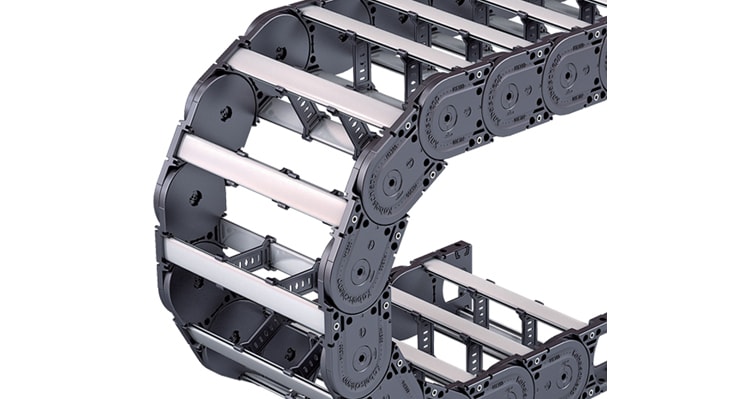

Tsubaki-KabelSchlepp® Cable Carriers: Keeping your sawmill machinery on track

Tsubaki-KabelSchlepp® Cable Carriers are often used within sawmills and on material handling equipment. The Tsubaki-KabelSchlepp® M Series and S/SX Series products both offer outstanding durability to extend equipment life and reduce costly downtime.

- M Series: A variable cable carrier with extensive accessories and crossbar options. The Tsubaki-KabelSchlepp® offers an encapsulated, dirt-resistant stroke system and durable sidebands through robust link plate design. These carriers also offer a large selection of vertical and horizontal divider systems to ensure maximum life of your cables.

- S/SX Series: These extremely robust and sturdy steel cable carriers are ideal for heavy mechanical loads and rough environmental conditions. S/SX Series cable carriers feature side bands made of galvanized steel or corrosion-resistant and acid-resistant steel and feature very sturdy link plates. This allows for extensive unsupported lengths and high loads.

Do you want to learn more about how Tsubaki’s wide variety of forestry solutions can help optimize your sawmill operation’s productivity and profitability? Contact us and a Tsubaki representative will reach out to you with more information.